Dispersed Air Flotation Systems

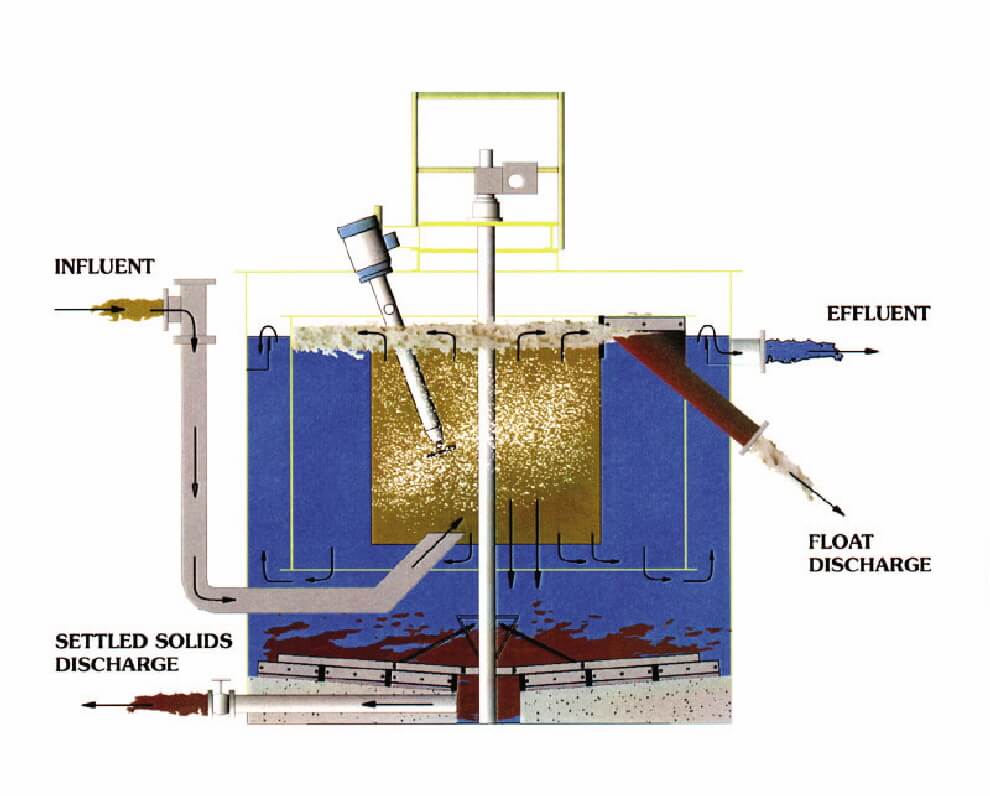

The KEE dispersed air floatation system is specifically designed for physical/chemical pre-treatment of wastewater.

At KEE, our Dispersed Air Flotation (DAF) technology offers an effective solution for removing suspended solids, oils, and greases from wastewater. By injecting tiny air bubbles into the effluent, contaminants are lifted to the surface, where they can be removed via mechanical skimming. This process ensures efficient separation, lower pollutant loads, and compliance with discharge standards.

With KEE services, you can trust our experienced engineers to upgrade your contaminant removal, improve your energy efficiency, and ensure regulatory compliance. Why not book a DAF system service online and secure high-quality service?

Premium Air Flotation Systems

In a DAF unit, pressurised air is released into the wastewater stream, forming fine bubbles that attach to suspended matter, allowing the removal of fats, oils, greases, and other solids while also reducing chemical demand in the downstream process. These systems work to enhance your overall wastewater treatment efficiency, producing clearer effluent for safe discharge.

Our DAF systems are widely used across:

- Municipal treatment plants to manage solids and scum loads.

- Industrial sites, such as food processing facilities, dairies, and breweries.

- Commercial operations where effluent quality and compliance are critical.

Benefits of KEE DAF Systems

- Highly efficient solids and oil removal.

- Improved effluent quality with reduced chemical use.

- Scalable designs for small to large flow rates.

- Reliable operation with low energy consumption.

KEE DAF Technology Solutions

Our engineering team provides design, installation, and integration of DAF units into new or existing wastewater treatment plants. Every system is tailored to site-specific flow rates, solids loadings, and compliance requirements.

Looking for ongoing support? KEE also offers specialist DAF system servicing, performance optimisation, and 24/7 emergency call-outs to keep your flotation unit running reliably. Contact our team today to discuss your needs.

FAQs

What is the difference between dissolved and dispersed air flotation systems?

Both Dissolved Air Flotation (DAF) and Dispersed Air Flotation are processes designed to clarify wastewater by using buoyant forces to lift suspended solids to the surface. However, they differ significantly in how they generate and apply air bubbles:

- Dissolved Air Flotation (DAF): This method saturates a portion of the wastewater with air at high pressure within a pressure vessel. When this supersaturated water is released into the Air Flotation tank at atmospheric pressure, microscopic bubbles are formed.

- Dispersed Air Flotation: This process uses a mechanical system, often involving a high-speed impeller or fine diffusers, to inject air directly into the wastewater at atmospheric pressure. This method produces slightly larger bubbles, which are also effective for clarification.

The choice between the two methods depends on the specific application. Dispersed Air Flotation systems are often preferred for their simplicity and ability to handle specific wastewater streams without the energy demands associated with high-pressure systems.

Why should you use dispersed air flotation systems for wastewater?

Dispersed Air Flotation systems offer distinct advantages for treating industrial and municipal wastewater, making them a powerful choice within the realm of Air Flotation technologies:

- Robustness and Simplicity: Unlike DAF systems, which rely on pressure vessels and sophisticated control systems, Dispersed Air Flotation uses a straightforward mechanical process, resulting in fewer components that can fail and simpler maintenance procedures.

- Effective Solids Handling: These systems are highly effective at handling wastewater streams with variable quality and high solids loading, including challenging sludges and oils.

Cost-Effective Operation: By eliminating the need for a dedicated pressure saturation system, Dispersed Air Flotation can often be more energy-efficient and cost-effective to install and operate, particularly in applications where the formation of extremely fine micro-bubbles is not strictly required.